Summer Supply Chain Blues

How many chips does a truck need?

How many chips does a truck need?

With freight demand soaring, you’d think truck makers would be producing a record number of trucks in 2021. But like all other technology enabled industries, truck makers are having a hard time sourcing components, especially those with chips. According to ACT Research, July Class 8 truck production sank to a 15 month low. Truck makers around the world idled factories for days and some for weeks to allow for the supply chain to catch up with production. The question everyone is asking, is how many chips are actually in each truck and why is it so hard to get them?

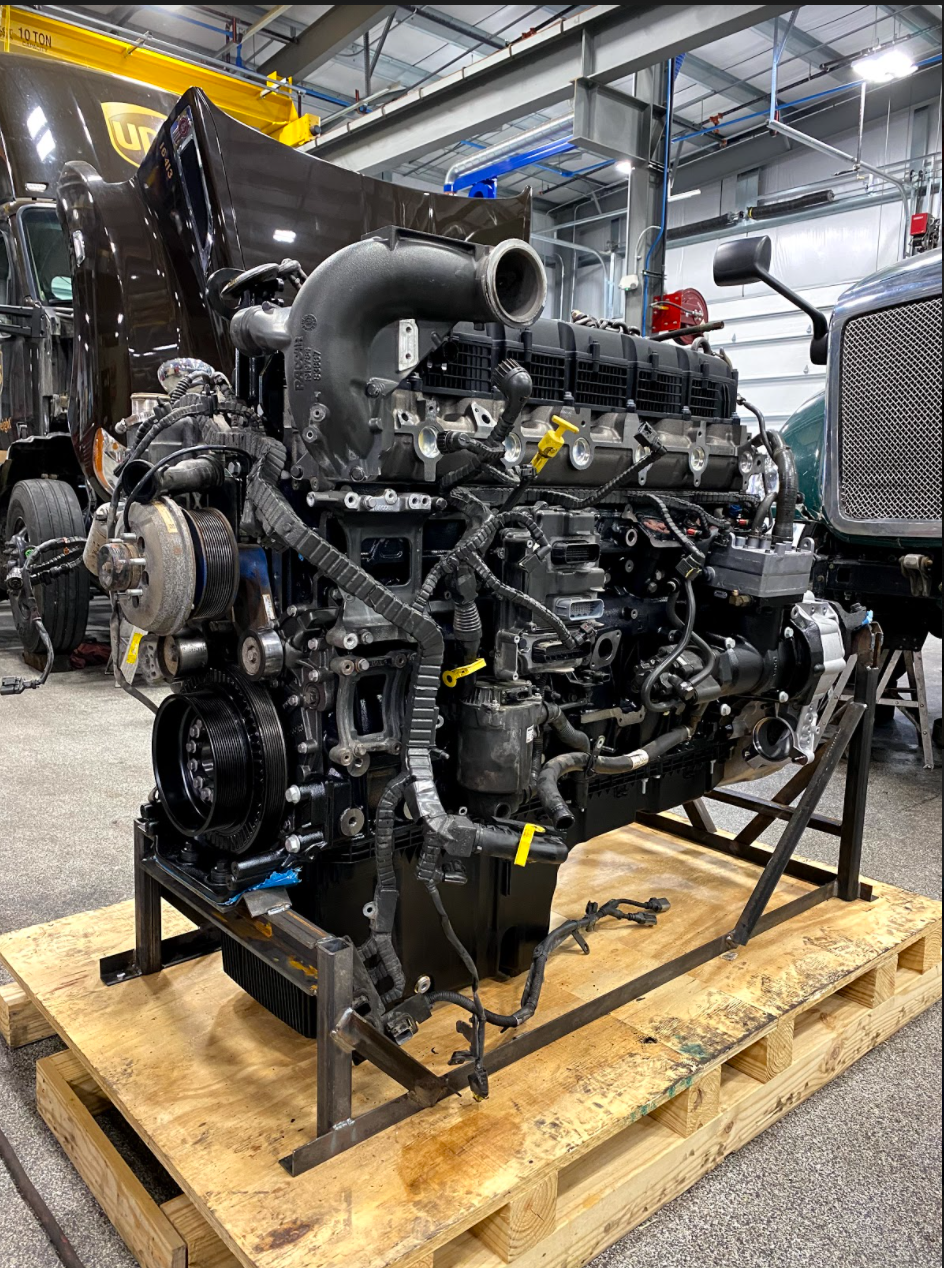

Not to surprise you, but this is a complicated question. There are two ways to answer the “how many chips per truck” question. First, you can look at the type of chip. There are different levels of complexity. For example, a chip that processes one type of function, like measuring a data input such as NOX levels off a sensor, are fairly inexpensive and mass produced. However, some chips perform millions of functions from many data sources at once. These generally are chips that power engine control units (ECUs), collision avoidance systems, or fleet management systems. These can be expensive and more akin to the chips that power your IPhone rather than your TV remote. As we write this in late summer 2021, both types of chips are in short supply and the price and availability of each are skyrocketing.

Now on to the next question. How many of each of the chips are in each truck? Well, in short, when asked this question each manufacturer referenced that this is proprietary knowledge. But from the best we can gather from looking at individual components on each truck and across the different brands and models, we believe the following:

Now, I want to stress that this is a best estimate and is by no means perfect.

How many chips does a truck need? The answer is it depends – on brand, model, application, and options.

The supply chain issues are going to persist until mid 2022. Truck production will continue to be unpredictable, driving up values of any new or used trucks that are available on the ground and making it difficult to predict when you would receive trucks on order.

Plan as far ahead as possible, and factor in contingencies. Search around for available equipment that is on the ground, and avoid auctions during these times as you will likely pay retail or higher! When you do find equipment that will work, you have to act fast.

We can assist you in finding the best way to plan for your truck equipment needs. We have new Kenworth trucks on the ground, available for delivery if needed. In addition, we can give you up to date information on our inbound inventory and give you our best estimate as when it is to be expected. We are here to help in these uncertain times!